세라믹 도가니 Leco 528-018. LECO CS230 용 탄소황 도가니 및 CS 도가니 제조업체 . Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 안. 탄소 황 분석기 원소 분석에 사용됩니다.

읽기 더 많은...

Al um ina 튜브 양면 개방형 은 일반적으로 다양한 산업 및 실험실 응용 분야 에서 사용 됩니다 . 가열 , 냉각 및 건조 와 같은 공정 에 사용 하기 에 이상적 이며 우수한 열 및 전기 절연 을 제공 할 수 있습니다 .

읽기 더 많은...

Alumina 세라믹 기판 시트 는 고성능 , 신뢰성 및 내구성 이 요구 되는 용도 에 이상적인 선택 입니다 . _ _ _ _ 다양한 용도 에 맞게 다양한 크기 와 두께 로 제공 됩니다 . _ _

읽기 더 많은...

Bone Ash Cupels로 비교할 수 없는 수준의 순도를 달성하십시오. 불순물과 불필요한 요소를 제거하도록 설계된 이 컵은 귀금속의 진정한 본질을 추출할 수 있게 해줍니다.

읽기 더 많은...

반토 관 이점: 높은 내열성, 좋은 찬 저항 내열성, 산과 알칼리 부식에 저항 . 긴 수명. OEM이 승인되었습니다.

읽기 더 많은...

원형 알루미나 세라믹 막대는 다른 세라믹보다 중량 대비 강도가 높으며 더 가볍고 더 강한 부품을 제조하는 데 사용할 수 있습니다. 다양한 크기와 모양으로 제공됩니다.

읽기 더 많은...

루미나 도가니 와 보트는 금속 및 비금속 재료 샘플 용해뿐만 아니라 실험실 및 산업 분석에 널리 사용됩니다. 다양한 크기와 모양으로 제공됩니다.

읽기 더 많은...

952018.906 TA Instruments TA Q500/Q50/TGA 2950/2050 용 100μl 백금/Pt 도가니( 샘플 팬) . TA 도가니 및 DSC 샘플 팬 제조업체 . TA Instruments tga 분석기 대체 샘플 컵.

읽기 더 많은...

지르코니아 세라믹은 샤프트, 플런저, 밀봉 구조, 자동차 산업, 석유 시추 장비, 전기 장비의 절연 부품, 세라믹 나이프, 세라믹 이발기 예비 부품, 고밀도, 굽힘 강도 및 파괴 강인에 사용됩니다. 우리는 고객의 도면, 샘플 및 성능 요구 사항에 따라 제품을 공급할 수 있습니다.12

읽기 더 많은...

1. 다른 크기의 Platinum/PT Crucible 수행필요에 따라 .2. Platinum/PT Crucibles의 설계 도면 또는 사양을 보내주십시오. 백금/PT 도가니 제조업체 .CS CERMAIC CO.,LTD

읽기 더 많은...

Advantages of transparent quartz plate:

1. Quartz glass plate can withstand a high temperature without cracking or melting. Long term use at 1100 ℃, short term use at 1450 ℃.

2. It has excellent transparency and is very suitable for applications requiring high optical clarity such as spectroscopy, optics, and laser technology.

3. The low coefficient of thermal expansion means that it can withstand temperature fluctuations without cracking or warping.

4. It is very durable, and its mechanical strength makes it resistant to impacts and scratches, making it durable.

5. Easy to clean with high-pressure water, steam, or ultrasound, it is a low maintenance material.

6. It is resistant to ultraviolet radiation and is very suitable for applications that require exposure to ultraviolet radiation, such as curing systems for printing machines, lithography machines, etc.

Descriptions of transparent quartz plate:

1. These plates are made from 99.98% pure quartz glass material, ensuring superior optical clarity and high-temperature tolerance.

2. They have an excellent ability to block UV radiation, making them essential in applications such as UV curing, light filtering, and sterilization.

3. Quartz glass plates are highly versatile and can be utilized in a variety of applications. From laboratory experiments to semiconductor manufacturing, these plates offer superior performance and precision.

4. Available in a range of sizes, thicknesses, and shapes, making them highly versatile.

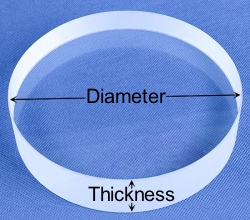

Size details of transparent quartz plate:

| Size details of quartz glass disc | |||||||

| Item NO. |

Diameter

(mm)

|

Thickness

(mm)

|

Purity | Item NO. |

Diameter

(mm)

|

Thickness

(mm)

|

Purity |

| CS-QTZ-P001 | 10 | 1 | 99.98% | CS-QTZ-P015 | 70 | 5 | 99.98% |

| CS-QTZ-P002 | 15 | 1 | 99.98% | CS-QTZ-P016 | 80 | 2 | 99.98% |

| CS-QTZ-P003 | 15 | 2 | 99.98% | CS-QTZ-P017 | 80 | 3 | 99.98% |

| CS-QTZ-P004 | 20 | 1 | 99.98% | CS-QTZ-P018 | 80 | 5 | 99.98% |

| CS-QTZ-P005 | 20 | 2 | 99.98% | CS-QTZ-P019 | 90 | 5 | 99.98% |

| CS-QTZ-P006 | 25 | 1 | 99.98% | CS-QTZ-P020 | 100 | 1 | 99.98% |

| CS-QTZ-P007 | 25 | 2 | 99.98% | CS-QTZ-P021 | 100 | 2 | 99.98% |

| CS-QTZ-P008 | 30 | 1 | 99.98% | CS-QTZ-P022 | 100 | 3 | 99.98% |

| CS-QTZ-P009 | 30 | 2 | 99.98% | CS-QTZ-P023 | 100 | 5 | 99.98% |

| CS-QTZ-P010 | 60 | 1 | 99.98% | CS-QTZ-P024 | 150 | 2 | 99.98% |

| CS-QTZ-P011 | 60 | 2 | 99.98% | CS-QTZ-P025 | 150 | 3 | 99.98% |

| CS-QTZ-P012 | 60 | 5 | 99.98% | CS-QTZ-P026 | 150 | 5 | 99.98% |

| CS-QTZ-P013 | 70 | 2 | 99.98% | CS-QTZ-P027 | 10-90 | 1-20 | 99.98% |

| CS-QTZ-P014 | 70 | 3 | 99.98% | CS-QTZ-P028 | 91-450 | 1-20 | 99.98% |

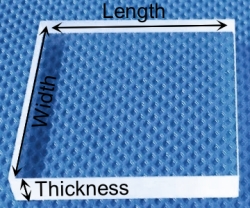

| Size details of quartz glass plate | |||||||||

| Item NO. |

Length

(mm)

|

Width

(mm)

|

Thickness

(mm)

|

Purity | Item NO. |

Length

(mm)

|

Width

(mm)

|

Thickness

(mm)

|

Purity |

| CS-QTZ-P1001 | 15 | 5 | 1 | 99.98% | CS-QTZ-P1013 | 70 | 70 | 5 | 99.98% |

| CS-QTZ-P1002 | 10 | 10 | 1 | 99.98% | CS-QTZ-P1014 | 80 | 80 | 5 | 99.98% |

| CS-QTZ-P1003 | 15 | 15 | 1 | 99.98% | CS-QTZ-P1015 | 100 | 100 | 1 | 99.98% |

| CS-QTZ-P1004 | 15 | 15 | 2 | 99.98% | CS-QTZ-P1016 | 100 | 100 | 1.5 | 99.98% |

| CS-QTZ-P1005 | 20 | 20 | 1 | 99.98% | CS-QTZ-P1017 | 100 | 100 | 2 | 99.98% |

| CS-QTZ-P1006 | 20 | 20 | 2 | 99.98% | CS-QTZ-P1018 | 100 | 100 | 3 | 99.98% |

| CS-QTZ-P1007 | 25 | 25 | 1 | 99.98% | CS-QTZ-P1019 | 100 | 100 | 5 | 99.98% |

| CS-QTZ-P1008 | 25 | 25 | 2 | 99.98% | CS-QTZ-P1020 | 150 | 150 | 2 | 99.98% |

| CS-QTZ-P1009 | 30 | 30 | 1 | 99.98% | CS-QTZ-P1021 | 150 | 150 | 3 | 99.98% |

| CS-QTZ-P1010 | 30 | 30 | 2 | 99.98% | CS-QTZ-P1022 | 150 | 150 | 5 | 99.98% |

| CS-QTZ-P1011 | 60 | 60 | 1 | 99.98% | CS-QTZ-P1023 | 10-450 | 10-450 | 1-20 | 99.98% |

| CS-QTZ-P1012 | 60 | 60 | 2 | 99.98% | |

||||

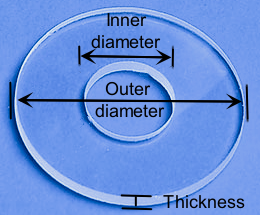

| Size details of quartz glass circle ring | ||||

| Item NO. |

Outer

diameter

(mm)

|

Inner

diameter

(mm)

|

Thickness

(mm)

|

Purity |

| CS-QTZ-H001 | 9 | 5 | 1-10 | 99.98% |

| CS-QTZ-H002 | 16 | 6 | 1-10 | 99.98% |

| CS-QTZ-H003 | 30 | 20 | 1-10 | 99.98% |

| CS-QTZ-H004 | 42 | 30 | 5-20 | 99.98% |

| CS-QTZ-H005 | 56 | 24 | 5-20 | 99.98% |

| CS-QTZ-H006 | 65 | 30 | 5-20 | 99.98% |

| CS-QTZ-H007 | 73 | 55 | 5-20 | 99.98% |

| CS-QTZ-H008 | 84 | 42 | 5-20 | 99.98% |

| CS-QTZ-H009 | 95 | 65 | 5-20 | 99.98% |

| CS-QTZ-H010 | 102 | 80 | 5-20 | 99.98% |

| CS-QTZ-H011 | 103 | 83 | 8 | 99.98% |

| CS-QTZ-H012 | 120 | 55 | 5-20 | 99.98% |

| CS-QTZ-H013 | 135 | 95 | 5-20 | 99.98% |

| CS-QTZ-H014 | 165 | 100 | 5-20 | 99.98% |

Parameters of quartz glass plate:

| Chemical composition: | SiO2 99.9% |

| Density: | 2.2(g/cm3) |

| Degree of hardness moh' scale: | 6.6 |

| Melting point: | 1732℃ |

| Working temperature: | 1100℃ |

| Max temperature can reach in a short time: | 1450℃ |

| Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

| Visible light transmittance: | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value: | 10000 times than ordinary glass |

| Annealing point: | 1215℃ |

| Softening point: | 1730℃ |

Applications of transparent quartz plate:

1. Optical applications: Quartz glass plates are widely used in optical instruments like microscopes, telescopes, and cameras.

2. Chemical applications: These plates can be used as covers for reaction vessels, gas samples, or liquid samples.

3. Semiconductor applications: They are also used in semiconductor manufacturing processes, such as chemical vapor deposition (CVD) and wafer cleaning. Quartz wafers have a high thermal resistance, high chemical resistance, and excellent surface flatness, making them ideal for use in lithography and other process steps.

4. Medical applications: They are used in medical equipment like spectroscopy devices, refractometers, and other specialized instruments.

5. Solar applications: They are used in the manufacturing of solar cells and panels.

6. Aerospace applications: They used in the aerospace industry as protective covers for sensors, probes, and communication systems. They are also used as windows for aircraft and spacecraft cabins due to their high-temperature resistance, high strength, and low thermal expansion.

7. Research and development: Quartz glass plates are widely used in research and development to facilitate experimentation, as they are easily cleanable and have minimal reactivity with most materials. They are used as substrates for assembling nanodevices, as windows for high-pressure experiments, and as a substrate for conducting materials research.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of quartz glass plate, such as shape, dimension, quantity, application etc.

Q2. How do I maintain quartz glass plates?

Regularly clean quartz glass plates. In order to maintain the optical quality of glass, it is important to wear clean gloves for processing and store it in a clean and dust-free environment.

Q3. How long is the lifespan of a quartz glass plate?

The lifespan of a quartz glass plate depends on its usage and exposure to harsh chemicals, high temperatures, and other environmental factors. If maintained properly, a quartz glass plate can last for many years.

Q4. What is the lead time for the quartz glass plate?

The lead time is dependent on the size and quantity required. Please contact us for more information.

How to clean transparent quartz plate:

1. Use a mild soap or detergent mixed with warm water. Avoid using harsh chemicals or abrasive cleaners that can damage the quartz glass.

2. Immerse the quartz glass plates in the cleaning solution for at least 10-15 minutes.

3. 담근 후 부드러운 솔이나 천을 사용하여 플레이트를 부드럽게 문지릅니다. 석영 유리 표면이 긁히거나 손상될 수 있으므로 너무 세게 누르지 마십시오.

4. 깨끗한 물을 사용하여 플레이트를 철저히 헹구어 세척액의 흔적을 모두 제거합니다.

5. 부드럽고 마른 천이나 수건을 사용하여 접시를 닦습니다.

품질 테스트 표준:

1. 석영 유리 의 육안 검사 손상 또는 불규칙의 징후가 없는지 확인하십시오 .

2. 정확성을 확인하기 위해 석영 유리판 의 길이, 너비 및 두께를 측정합니다 .

3. 석영 유리판 을 광원에 대고 투명도를 검사합니다. 투명한 석영 유리는 왜곡이 거의 없이 빛이 쉽게 통과할 수 있어야 합니다.

4. 석영 유리판 표면에 소량의 물을 붓고 물의 거동을 관찰합니다. 물이 구슬처럼 올라와 석영 유리판 의 표면을 제대로 적시지 않으면 표면에 불순물이 코팅된 것일 수 있습니다.

5. 석영 유리판 의 재료 및 화학 성분 확인 .

패킹 방법:

왜 우리를 선택 했습니까?

1. 개인의 니즈에 맞는 맞춤형 서비스를 제공합니다.

2. 우리는 성공의 좋은 기록을 가진 경험이 풍부한 전문가입니다.

3. 우리는 우수한 고객 서비스를 제공하고 모든 문의에 신속하게 응답합니다.

4. 우리는 전투적인 가격을 제공하고 귀하의 자금이 최고의 가치를 받을 수 있도록 노력합니다.

5. 최신 기술과 도구를 사용하여 프로젝트가 최고 수준으로 완료되도록 합니다.

알루미나 지르코니아 복합 비드 ZTA/ATZ 밀링 볼

알루미나 지르코니아 복합 비드 ZTA/ATZ 밀링 볼

알루미나 지르코니아 복합 비드 밀링 볼은 알루미나와 지르코니아의 특성을 결합하여 내마모성, 인성 및 기타 필요한 특성을 향상시킵니다. 다양한 크기와 순도로 제공됩니다.

다공성 세라믹 진공 척 알루미나 진공 척

다공성 세라믹 진공 척 알루미나 진공 척

다공성 세라믹 진공 척 알루미나 진공 척은 균일한 진공 분포, 맞춤형 다공성, 내화학성 및 온도 저항성, 낮은 오염 위험, 에너지 효율성을 가지고 있습니다.

NGB801556 /GB399860 Pt 99.95%와 동일한 크기의 뚜껑이 있는 190μl Pt/백금 샘플 팬

NGB801556 /GB399860 Pt 99.95%와 동일한 크기의 뚜껑이 있는 190μl Pt/백금 샘플 팬

DSC 204 F1 Phoenix®, DSC 200 F3 Maia®, DSC 3500 Sirius 및 DSC 214 Polymaï¼ TG 209 F1 Libra® 및 TG 209 F3 Tarsusï¼ STA 449 F1/F3 Jupiter® 및 DSC 404 F1/F3 Pegasusï¼ DSC 404 F1/F3 페가수스ï¼ STA 449 F1/F3 주피터 Netzsch TDA DSC 및 TGA 측정용. Netzsch 도가니 및 샘플 컵 제조업체입니다. Netzsch Instruments의 DSC 샘플 팬을 대체할 수 있는 좋은 제품입니다.12

95% 알루미나 세라믹 밀 단지 볼 밀링 용기

95% 알루미나 세라믹 밀 단지 볼 밀링 용기

알루미나 세라믹 볼 밀 캔은 내마모성이 뛰어난 분쇄 용기입니다. 동시에 일반 세라믹 볼 연삭 탱크와 99% 도자기 세라믹 볼 연삭 탱크도 제공합니다.

SiC 세라믹 볼 검정 광택 고성능 탄화규소 볼 크기 2mm 또는 3mm

SiC 세라믹 볼 검정 광택 고성능 탄화규소 볼 크기 2mm 또는 3mm

당사의 재결정된 SiC 제품은 순도가 높은 반면, 당사의 반응 결합 및 소결 탄화규소 볼은 높은 기계적 강도를 가지고 있습니다. 낮은 열팽창 계수, 극도의 내식성, 높은 경도 및 자체 윤활 특성.

뚜껑이 있는 100μl 흑연 도가니 6.0*4.5mm

뚜껑이 있는 100μl 흑연 도가니 6.0*4.5mm

TA Instruments 용 TA 흑연 도가니 샘플 팬 및 뚜껑 . TA 도가니 및 DSC 샘플 팬용 제조업체 .TA Instruments의 우수한 대체 샘플 컵.

전문 팀 서비스 !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522