세라믹 도가니 Leco 528-018. LECO CS230 용 탄소황 도가니 및 CS 도가니 제조업체 . Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 안. 탄소 황 분석기 원소 분석에 사용됩니다.

읽기 더 많은...

Al um ina 튜브 양면 개방형 은 일반적으로 다양한 산업 및 실험실 응용 분야 에서 사용 됩니다 . 가열 , 냉각 및 건조 와 같은 공정 에 사용 하기 에 이상적 이며 우수한 열 및 전기 절연 을 제공 할 수 있습니다 .

읽기 더 많은...

Alumina 세라믹 기판 시트 는 고성능 , 신뢰성 및 내구성 이 요구 되는 용도 에 이상적인 선택 입니다 . _ _ _ _ 다양한 용도 에 맞게 다양한 크기 와 두께 로 제공 됩니다 . _ _

읽기 더 많은...

Bone Ash Cupels로 비교할 수 없는 수준의 순도를 달성하십시오. 불순물과 불필요한 요소를 제거하도록 설계된 이 컵은 귀금속의 진정한 본질을 추출할 수 있게 해줍니다.

읽기 더 많은...

반토 관 이점: 높은 내열성, 좋은 찬 저항 내열성, 산과 알칼리 부식에 저항 . 긴 수명. OEM이 승인되었습니다.

읽기 더 많은...

원형 알루미나 세라믹 막대는 다른 세라믹보다 중량 대비 강도가 높으며 더 가볍고 더 강한 부품을 제조하는 데 사용할 수 있습니다. 다양한 크기와 모양으로 제공됩니다.

읽기 더 많은...

루미나 도가니 와 보트는 금속 및 비금속 재료 샘플 용해뿐만 아니라 실험실 및 산업 분석에 널리 사용됩니다. 다양한 크기와 모양으로 제공됩니다.

읽기 더 많은...

952018.906 TA Instruments TA Q500/Q50/TGA 2950/2050 용 100μl 백금/Pt 도가니( 샘플 팬) . TA 도가니 및 DSC 샘플 팬 제조업체 . TA Instruments tga 분석기 대체 샘플 컵.

읽기 더 많은...

지르코니아 세라믹은 샤프트, 플런저, 밀봉 구조, 자동차 산업, 석유 시추 장비, 전기 장비의 절연 부품, 세라믹 나이프, 세라믹 이발기 예비 부품, 고밀도, 굽힘 강도 및 파괴 강인에 사용됩니다. 우리는 고객의 도면, 샘플 및 성능 요구 사항에 따라 제품을 공급할 수 있습니다.12

읽기 더 많은...

1. 다른 크기의 Platinum/PT Crucible 수행필요에 따라 .2. Platinum/PT Crucibles의 설계 도면 또는 사양을 보내주십시오. 백금/PT 도가니 제조업체 .CS CERMAIC CO.,LTD

읽기 더 많은...

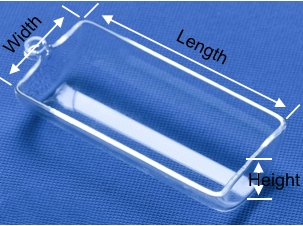

1. High Purity: Quartz glass boats have very high purity, They are resistant to contamination and do not react with most chemicals, making them suitable for use in many industrial processes.

2. High Temperature Tolerance: They are resistant to high temperatures,long term use at 1100 ℃, short term use at 1450 ℃.

3. Chemical Resistance: They have strong resistance to chemicals and are very suitable for use in harsh chemical environments.

4. High optical clarity: They have high optical clarity and are ideal for optical applications such as lenses, prisms, and windows.

5. Economical: Quartz glass boats have a high cost-effectiveness and lower life cost compared to other materials, as they have high durability and wear resistance.

1. Quartz glass boats are made of premium quality quartz materials that ensure superior durability and long-lasting performance.

2. For extreme purity requirements, this quartz glass boats are the perfect choice.

3. They have high chemical resistance, they are ideal for containing and transferring aggressive chemicals such as acids, alkalis, and solvents.

4. Quartz glass boats have excellent optical clarity, they are free from impurities, so they don't obstruct the passage of light.

| Quartz glass boats size details | ||||||

| Item NO. |

Length

(mm)

|

Width

(mm)

|

Height

(mm)

|

Wall thickness

(mm)

|

Hole | Purity |

| CS-QZT-Z001 | 50 | 10 | 5 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z002 | 100 | 10 | 5 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z003 | 50 | 15 | 7.5 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z004 | 100 | 15 | 7.5 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z005 | 50 | 20 | 10 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z006 | 100 | 20 | 10 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z007 | 50 | 25 | 12.5 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z008 | 100 | 25 | 12.5 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z009 | 50 | 30 | 15 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z010 | 100 | 30 | 15 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z011 | 200 | 30 | 15 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z012 | 50 | 40 | 20 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z013 | 100 | 40 | 20 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z014 | 200 | 40 | 20 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z015 | 50 | 50 | 25 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z016 | 100 | 50 | 25 | 1.5-2 | with hole | 99.98% |

| CS-QZT-Z017 | 200 | 50 | 25 | 1.5-2 | with hole | 99.98% |

| CS-QTZ-Z018 | 43 | 37 | 19 | 2 | / | 99.99% |

| CS-QTZ-Z019 | 45 | 38 | 26 | 2 | / | 99.99% |

| CS-QTZ-Z020 | 45 | 28 | 18 | 2 | / | 99.99% |

| CS-QTZ-Z021 | 55 | 43 | 21 | 2 | / | 99.99% |

| CS-QTZ-Z022 | 60 | 38 | 23 | 2 | / | 99.99% |

| CS-QTZ-Z023 | 65 | 57 | 25 | 2 | / | 99.99% |

| CS-QTZ-Z024 | 65 | 33 | 16 | 2 | / | 99.99% |

| CS-QTZ-Z025 | 65 | 57 | 25 | 2 | / | 99.99% |

| CS-QTZ-Z026 | 70 | 28 | 17 | 2 | / | 99.99% |

| CS-QTZ-Z027 | 85 | 43 | 18 | 2 | / | 99.99% |

| CS-QTZ-Z028 | 105 | 68 | 31 | 2.5 | / | 99.99% |

| CS-QTZ-Z029 | 105 | 43 | 26 | 2.5 | / | 99.99% |

| CS-QTZ-Z030 | 105 | 23 | 16 | 2.5 | / | 99.99% |

| CS-QTZ-Z031 | 105 | 23 | 21 | 2.5 | / | 99.99% |

| CS-QTZ-Z032 | 105 | 33 | 21 | 2.5 | / | 99.99% |

| CS-QTZ-Z033 | 105 | 43 | 21 | 2.5 | / | 99.99% |

| CS-QTZ-Z034 | 105 | 53 | 31 | 2.5 | / | 99.99% |

| CS-QTZ-Z035 | 105 | 43 | 26 | 2.5 | / | 99.99% |

| CS-QTZ-Z036 | 105 | 43 | 21 | 2.5 | / | 99.99% |

| CS-QTZ-Z037 | 105 | 23 | 16 | 2.5 | / | 99.99% |

| CS-QTZ-Z038 | 105 | 23 | 21 | 2.5 | / | 99.99% |

| CS-QTZ-Z039 | 105 | 33 | 21 | 2.5 | / | 99.99% |

| CS-QTZ-Z040 | 105 | 53 | 31 | 2.5 | / | 99.99% |

| CS-QTZ-Z041 | 108 | 58 | 31 | 2.5 | / | 99.99% |

| CS-QTZ-Z042 | 155 | 43 | 21 | 3 | / | 99.99% |

| CS-QTZ-Z043 | 165 | 78 | 41 | 3 | / | 99.99% |

| CS-QTZ-Z044 | 250 | 43 | 21 | 3 | / | 99.99% |

| CS-QTZ-Z045 | 255 | 43 | 19 | 3 | / | 99.99% |

| CS-QTZ-Z046 | 295 | 43 | 23 | 3 | / | 99.99% |

OEM/ODM is acceptable. Your goods will be produced exactly according to your drawings or inquiry

| Chemical composition: | SiO2 99.9%;99.98% |

| Density: | 2.2(g/cm3) |

| Degree of hardness moh' scale: | 6.6 |

| Melting point: | 1732℃ |

| Working temperature: | 1100℃ |

| Max temperature can reach in a short time: | 1450℃ |

| Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

| Visible light transmittance: | above 93% |

| UV spectral region transmittance: | 80% |

| Resistance value: | 10000 times than ordinary glass |

| Annealing point: | 1215℃ |

| Softening point: | 1730℃ |

1. Chemical transportation: Quartz glass boats are commonly used in chemical transportation applications to hold and transport chemicals such as acids, alkalis, and solvents. The chemical resistance of quartz glass makes it an ideal material for this purpose.

2. Sample preparation: They are very useful in sample preparation applications, especially for analytical chemistry. Samples can be placed inside the boat and heated to high temperatures for analysis.

3. Semiconductor manufacturing: Used in semiconductor manufacturing for the transportation and storage of semiconductor wafers during the various stages of production. The high purity and low contamination properties of quartz glass makes it an ideal material for this application.

4. Optical handling: They are also used in handling and transportation of optical components primarily for high-precision optical applications.

5. Crystal growth:Used in crystal growth applications, especially in the production of single crystals. The high purity and heat resistance properties of quartz glass make it a suitable material for this application.

6. Thin film deposition: Commonly used in thin film deposition applications such as atomic layer deposition (ALD) and chemical vapor deposition (CVD). The boats are used to hold substrates during deposition processes.

7. Biological analysis: They are used in biological analysis applications such as microscopy and spectroscopy. The boats can be used to hold and analyze biological samples under high temperatures and extreme conditions.

Q1. What information should we supply to get a quote?

Please offer the specification of quartz glass boat, such as shape, dimension, quantity, application etc.

Q2. What are the benefits of quartz glass boats?

Quartz glass boats have several benefits over other materials, including their high purity, chemical resistance, low thermal expansion coefficient, and their ability to withstand high temperatures and thermal shocks. They are also transparent to light, making it easy to monitor the sample during processing.

Q3. Can quartz glass boats be reused?

A: Yes, quartz glass boats can be reused multiple times, provided they are cleaned and inspected carefully after each use to avoid contamination.

Q4. How long do quartz glass boats last?

Quartz glass boats have a long lifespan, as they are highly durable and resistant to most chemicals and thermal stresses. However, their lifespan can be affected by exposure to extreme conditions or harsh chemicals, so proper maintenance and care are important to ensure their longevity.

1. Remove any remaining material from the quartz boat using a soft brush or soft cloth.

2. Fill a container with warm water and add a small amount of detergent.

3. Submerge the quartz boat in the detergent water and let it soak for several minutes.

4. Use a soft brush or cloth to gently scrub the inside and outside of the quartz boat, paying special attention to any stubborn stains or deposits.

5. Rinse the quartz boat thoroughly with clean water to remove all detergent residue.

6. Dry the quartz boat with a soft cloth or let it air dry.

7. Store the clean and dry quartz boat in a clean, dry location until its next use.

1. Visual inspection of the quartz boat for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the quartz boat to check for accuracy.

3. Hold the quartz boat against a light source and inspect it for transparency. Transparent quartz glass should allow light to pass through it easily with little to no distortion.

4. Pour a small amount of water on the surface of the quartz boat and observe the behavior of the water. If the water beads up and does not properly wet the surface of the quartz boat, it may indicate a coating of impurities on the surface.

5. Verification of the material and chemical composition of the quartz boat.

1. We supply personalized and customized services to contact your personal needs.

2. We are experienced professionals with a good record of success.

3. 우리는 우수한 고객 서비스를 제공하고 모든 문의에 신속하게 응답합니다.

4. 우리는 전투적인 가격을 제공하고 귀하의 자금이 최고의 가치를 받을 수 있도록 노력합니다.

5. 최신 기술과 도구를 사용하여 프로젝트가 최고 수준으로 완료되도록 합니다.

99.99% 투명한 원통형 석영 도가니 실리카 유리 도가니

99.99% 투명한 원통형 석영 도가니 실리카 유리 도가니

원통형 석영 유리 도가니는 고온 응용 분야를 위해 특별히 제작된 특수 용기로 부식 및 화학적 공격에 대한 탁월한 내성을 제공합니다. 다양한 크기로 제공됩니다.

뚜껑 SiO2 유리 도가니가 있는 99.99% 투명한 원추형 석영 도가니

뚜껑 SiO2 유리 도가니가 있는 99.99% 투명한 원추형 석영 도가니

원추형 석영 유리 도가니는 고순도로 만들어집니다 .석영 유리는 원뿔 모양이며, 그의 디자인 은 다양한 크기로 제공되는 도가니 전체에 효율적인 열 전달 및 균일한 열 분배를 허용합니다 .

99.99% 투명한 정사각형 석영 유리 도가니 실리카 도가니

99.99% 투명한 정사각형 석영 유리 도가니 실리카 도가니

정방형 석영 유리 도가니는 완벽하게 정방형으로 설계되어 샘플을 위한 더 많은 공간을 제공하고 균일한 가열을 보장하여 정밀 실험 및 연구에 이상적인 선택입니다. 다양한 크기로 제공됩니다.

반도체 및 PV의 실리콘 결정 풀링용 고순도 용융 석영 도가니

반도체 및 PV의 실리콘 결정 풀링용 고순도 용융 석영 도가니

매우 깨끗하고 내열성이 뛰어난 고순도 석영 도가니는 고온에서 안정적인 성능을 보장하며 반도체 및 광전지 공정에 중요하며 용융된 실리콘을 잡아서 결정 막대를 끌어당깁니다.

투명한 99.98% 석영 유리 비이커

투명한 99.98% 석영 유리 비이커

99.98% 석영 유리 비이커는 경제적 이점이 높으며 정확한 측정과 정확한 결과를 요구하는 모든 실험실 또는 연구 시설의 필수 장비입니다. 다양한 크기로 제공됩니다.

전문 팀 서비스 !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522