세라믹 도가니 Leco 528-018. LECO CS230 용 탄소황 도가니 및 CS 도가니 제조업체 . Eltra 90148/90149/90150/90152 Horiba 905.200.380.001 Bruker: JW-N009250423 Alpha AR3818 SerCon: SC0893 LECO 5 28-018/002-301/002-302 Elementar 905.200.380.001 안. 탄소 황 분석기 원소 분석에 사용됩니다.

읽기 더 많은...

Al um ina 튜브 양면 개방형 은 일반적으로 다양한 산업 및 실험실 응용 분야 에서 사용 됩니다 . 가열 , 냉각 및 건조 와 같은 공정 에 사용 하기 에 이상적 이며 우수한 열 및 전기 절연 을 제공 할 수 있습니다 .

읽기 더 많은...

Alumina 세라믹 기판 시트 는 고성능 , 신뢰성 및 내구성 이 요구 되는 용도 에 이상적인 선택 입니다 . _ _ _ _ 다양한 용도 에 맞게 다양한 크기 와 두께 로 제공 됩니다 . _ _

읽기 더 많은...

Bone Ash Cupels로 비교할 수 없는 수준의 순도를 달성하십시오. 불순물과 불필요한 요소를 제거하도록 설계된 이 컵은 귀금속의 진정한 본질을 추출할 수 있게 해줍니다.

읽기 더 많은...

반토 관 이점: 높은 내열성, 좋은 찬 저항 내열성, 산과 알칼리 부식에 저항 . 긴 수명. OEM이 승인되었습니다.

읽기 더 많은...

원형 알루미나 세라믹 막대는 다른 세라믹보다 중량 대비 강도가 높으며 더 가볍고 더 강한 부품을 제조하는 데 사용할 수 있습니다. 다양한 크기와 모양으로 제공됩니다.

읽기 더 많은...

루미나 도가니 와 보트는 금속 및 비금속 재료 샘플 용해뿐만 아니라 실험실 및 산업 분석에 널리 사용됩니다. 다양한 크기와 모양으로 제공됩니다.

읽기 더 많은...

952018.906 TA Instruments TA Q500/Q50/TGA 2950/2050 용 100μl 백금/Pt 도가니( 샘플 팬) . TA 도가니 및 DSC 샘플 팬 제조업체 . TA Instruments tga 분석기 대체 샘플 컵.

읽기 더 많은...

지르코니아 세라믹은 샤프트, 플런저, 밀봉 구조, 자동차 산업, 석유 시추 장비, 전기 장비의 절연 부품, 세라믹 나이프, 세라믹 이발기 예비 부품, 고밀도, 굽힘 강도 및 파괴 강인에 사용됩니다. 우리는 고객의 도면, 샘플 및 성능 요구 사항에 따라 제품을 공급할 수 있습니다.12

읽기 더 많은...

1. 다른 크기의 Platinum/PT Crucible 수행필요에 따라 .2. Platinum/PT Crucibles의 설계 도면 또는 사양을 보내주십시오. 백금/PT 도가니 제조업체 .CS CERMAIC CO.,LTD

읽기 더 많은...

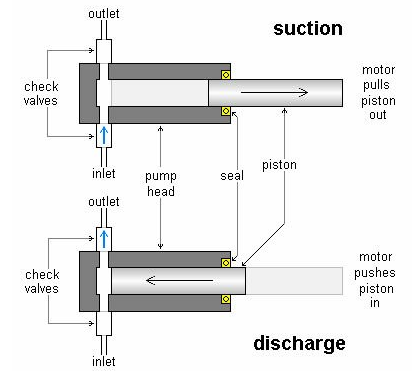

1. High Wear Resistance: Alumina ceramic shaft has excellent wear resistance and can withstand prolonged friction and impact, making it ideal for use in pumps.

2. High corrosion resistance: It can resist most acids, alkalis, and chemicals, and is suitable for use in harsh chemical environments.

3. Low thermal expansion: Low coefficient of thermal expansion enables it to withstand sudden changes in temperature without cracking, warping or deformation.

4. High strength: It has high compressive strength and is very suitable for use in high-pressure pumps.

5. Dimensional Stability: Alumina ceramic shaft maintain its shape and dimensions even under extreme stress or high-speed rotation, ensuring reliable operation over extended periods.

6. Electrically Insulating: It is excellent electrical insulators, which makes it ideal for use in pumps that handle conductive fluids.

7. Environmental Friendly: Non-toxic material and does not emit hazardous gases, making it an environmentally friendly material for use in pumps.

8. Cost-Effective: It has a longer lifespan and require less maintenance than traditional metal shafts, making it a cost-effective choice for pump manufacturers and operators.

1. This is a high-quality alumina ceramic shaft designed for use in pumps.

2. Made from premium grade alumina ceramic, this shaft is highly durable and capable of withstanding extreme temperatures and pressure.

3. This alumina ceramic shaft is engineered to resist corrosion and abrasion, making it ideal for use in harsh environments.

4. This shaft is designed to provide long-lasting reliability and functionality, helping to optimize your pump operations.

OEM: All sizes can be customized and can be made into various complex shapes with high dimensional accuracy. Please clearly provide the height, bottom diameter, top diameter, wall thickness and any special requirements. To speed up the quotation, please provide drawings.

| Shaft part: | 0.0015mm for axial dimensions |

| 0.001mm for circular degree | |

| 0.0025mm for concentricity | |

| 0.01 for roughness | |

| The minimum processing aperture: | 0.3mm, and depth limit 3mm |

| 0.002mm for axial dimensions of diameter 1mm aperture | |

| 0.02~0.04 for roughness | |

| Tolerance of plane processing: | 0.002 for flatness |

| 0.0015mm for measuring tolerance | |

| Ceramic processing thread: | processing internal thread size limit M2 |

| Thread accuracy gb-7h | |

| Unlimited size for external thread | |

| Thread accuracy gb-6g |

| Item | Test Condition | 95% AL2O3 | 99% AL2O3 | 99.5% AL2O3 | ||

| Physical properties | Density | g/cm3 | >3.6 | 3.89 | 3.96 | |

| Moisture absorption | % | 0 | 0 | 0 | ||

| Mechanical properties | ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | psiX103 | 20℃ | 358 | 550 | 550 | |

| Compressive strength | psiX103 | 20℃ | 2068(300) | 2600(377) | 2600(377) | |

| Fracture toughness | Mpa.m3/2 | K(l c) | 4.3 | 5.6 | 6 | |

| Thermal properties | Maximum use temperature | ℃ | 1450 | 1600 | 1650 | |

| Thermal expansion coefficient | 1X10-6/℃ | (25-1000℃) | 7.6 | 7.9 | 8.2 | |

| Thermal shock resistance | ℃ | Tc | 250 | 200 | 200 | |

| Thermal conductivity | w/mok | 20℃ | 16 | 30 | 30.4 | |

| Electrical properties | Volume resistivity | Ohm/cm2 | 100℃ | >1013 | >1014 | >1014 |

| Dielectric breakdown strength | KV/mm | 8.7(220) | 8.7(220) | 8.7(220) | ||

| Dielectric constant | (E) | 1MHz25℃ | 9 | 9.7 | 9.7 | |

| Dielectric constant (100MHz) | (E) | 9.5 | ||||

1. Alumina ceramic shaft is resistant to chemical corrosion and can withstand the harsh acidic and alkaline environments in chemical pumps.

2. Its high corrosion resistance enables it to withstand harsh environments in oil and gas pipeline drilling and production.

3. It is compatible with most pharmaceutical fluids and can be used in a pump for handling high-purity substances.

4. It has high wear resistance and can be used as a pump for treating water and grinding materials.

5. It can withstand the abrasiveness of mining applications and is very suitable for pumps used for processing minerals and extracting chemicals.

6. Alumina ceramic shaft can reduce corrosion and wear of HVAC pumps, improve their efficiency and lifespan.

7. It can reduce wear and prolong the service life of automotive pumps, making them very valuable in high-performance engines and vehicles.

Q1. What information should we supply to get a quote?

Please offer the specification of alumina ceramic shaft, such as shape, dimension, quantity, application etc.

Q2. How does alumina ceramic shaft compare to other materials used in pumps?

Compared to other materials used in pumps, alumina ceramic shaft offers superior wear resistance, corrosion resistance, and thermal stability. It is also more cost-effective than many other materials.

Q3. How long does alumina ceramic shaft last in a pump?

Alumina ceramic shaft can last for several years in a pump, depending on the operating conditions and maintenance schedule.

Q4. Is alumina ceramic shaft easy to install?

Alumina ceramic shaft can be installed in a pump using standard techniques. It is essential to use the appropriate procedures and tools to ensure the best results. Professional installation is recommended.

Q5. Is alumina ceramic shaft compatible with all types of fluids?

알루미나 세라믹 샤프트는 일반적으로 부식성 및 연마성 유체를 포함한 대부분의 유체와 호환됩니다. 그러나 재료 호환성 차트를 확인하고 적절한 재료 선택을 위해 제조업체와 상담하는 것이 필수적입니다.

1. 먼저 알루미나 세라믹 샤프트를 닦습니다.젖은 천으로 먼지와 이물질을 제거하십시오.

2. 부드러운 강모 브러시와 순한 세제 용액을 사용하여 알루미나 세라믹 샤프트를 문지릅니다 .

3. 알루미나 세라믹 샤프트 세척 깨끗한 물로 닦은 다음 부드러운 천으로 물기를 제거하십시오.

4. 다음에 사용할 때 알루미나 세라믹 샤프트가 건조한지 확인하십시오.

1. 알루미나 세라믹 샤프트 의 육안 검사 손상 또는 불규칙의 징후에 대해.

2. 알루미나 세라믹 샤프트 의 치수 측정정확성을 확인하기 위해.

3. 알루미나 세라믹 샤프트 에 핀홀 결함이 있는지 확인합니다 .

4. 알루미나 세라믹 샤프트 의 재료 및 화학 성분 확인 .

1. 개인의 니즈에 맞는 맞춤형 서비스를 제공합니다.

2. 우리는 성공의 좋은 기록을 가진 경험이 풍부한 전문가입니다.

3. 우리는 우수한 고객 서비스를 제공하고 모든 문의에 신속하게 응답합니다.

4. 우리는 전투적인 가격을 제공하고 귀하의 자금이 최고의 가치를 받을 수 있도록 노력합니다.

5. 최신 기술과 도구를 사용하여 프로젝트가 최고 수준으로 완료되도록 합니다.

알루미나 부싱 세라믹 절연체

알루미나 부싱 세라믹 절연체

케이블 종단 용 알루미나 부싱 세라믹 절연체 .여러 개의 플루트 및 캡 부싱, 리 엔트런트 부싱, 튜 블러 부싱, 배럴 및 원통형 부싱 등을 맞춤 제작할 수 있습니다.

알루미나 세라믹 볼 베어링 세라믹 부싱

알루미나 세라믹 볼 베어링 세라믹 부싱

고효율 및 경량의 알루미나 세라믹 볼 베어링 및 부싱 은 경도가 매우 높고 내마모성, 내열성 및 부식성이 우수합니다. 중국의 세라믹 베어링 공급업체.

95% ~ 99% 알루미나 세라믹 와셔 세라믹 씰 링

95% ~ 99% 알루미나 세라믹 와셔 세라믹 씰 링

Al um ina 는 그녀의 세라믹 씰 링 이 다양한 응용 분야 의 씰로 사용 되었습니다 . 이 링은 시간이 지나도 누출되거나 파손되지 않는 단단하고 안정적인 밀봉을 제공하도록 설계되었습니다. 모든 크기는 사용자 정의할 수 있습니다.

전문 팀 서비스 !

+86 0731-23455639

+86 0731-23455639 info@csceramic.com

info@csceramic.com +86 18273288522

+86 18273288522